Stainless Steel Materials

- Location

- Materials

- Decorative & Functional

Stainless Steel Finishes

Stainless Steel Specifications

Considerations:

- Location

- Materials

- Decorative & Functional

- Location

Location

Consider how the metal will react in different temperature conditions. Expansion and contraction will occur during extreme temperature changes.

Some colors may fade if placed in direct sun light.

High traffic areas may require heaver duty material.

Materials:

Stainless Steel:

- Very high recycled content, Stainless Steel typically has an 80% or greater overall recycled content depending on the product and application.

- 100% Recyclability, scrap stainless steel has considerable value so it isn’t discarded and won’t end up in a landfill. Unlike many other recycled materials, stainless steel isn’t “downgraded” during the recycling process. Stainless steel scrap can be re-melted to make new stainless steel of a grade equal to the old material; it can even be upgraded if needed with additional alloying elements.

- Extremely Long Life Cycle, because stainless steel is so durable and corrosion resistant, products made from it last much longer than those made from lesser materials. This long life cycle benefits the environment as new material and energy resources will be needed far less often to replace corroded or failed products.

- Surface corrosion can be avoided with appropriate specification. Even if corrosion is unlikely, occasional cleaning to remove surface deposits is suggested to maintain its pristine appearance. Surface cleaning suggestions can be viewed at www.architecturalmetals.org

Type 304

- Most common grade

- Recommended for interior use such as Column Covers, Wall panels, Furniture & Decorative Trims.

- Will usually provide a corrosion-free performance in climate-controlled indoor and mild outdoor applications.

- Should be specified with a smooth surface finish

- Regular cleaning should be planned

Type 316

- The second most common grade

- Recommended for the exterior use, indoor parking facilities and areas susceptible to car and aircraft exhaust, coastal or deicing salt, higher pollution levels and pool environments.

- Also known as marine grade stainless steel due to it’s increased resistance to chloride corrosion compared to type 304

Type 2205

- Used for more corrosive locations

- Significantly better corrosive resistant than Type 316

- Suggested for applications with high surface salt accumulations or salt water spray exposure.

- Also known as “Duplex” stainless steel, it has lower nickel and molybdenum contents than their austenitic counterparts of similar corrosion resistance. Due to the lower alloying content, duplex stainless steels can be lower in cost, especially in times of high alloy surcharges. Additionally, it may often be possible to reduce the section thickness of duplex stainless steel, due to its increased yield strength compared to austenitic stainless steel. The combination can lead to significant cost and weight savings compared to a solution in austenitic stainless steels.

Thicknesses most commonly used

- 18 Gauge, Flashings & Decorative Trims

- 16 Gauge, overall general use, Column Covers, Wall Panels

- 14 Gauge, high traffic areas, Column Covers, Wall Panels

- 12 Gauge, Parking garages, Bollards, Column Covers, Wall Panels

Of the 4 gauges, 12 gauge is not easily formed due to the tonnage required to bend the material.

Commonly Specified Finishes

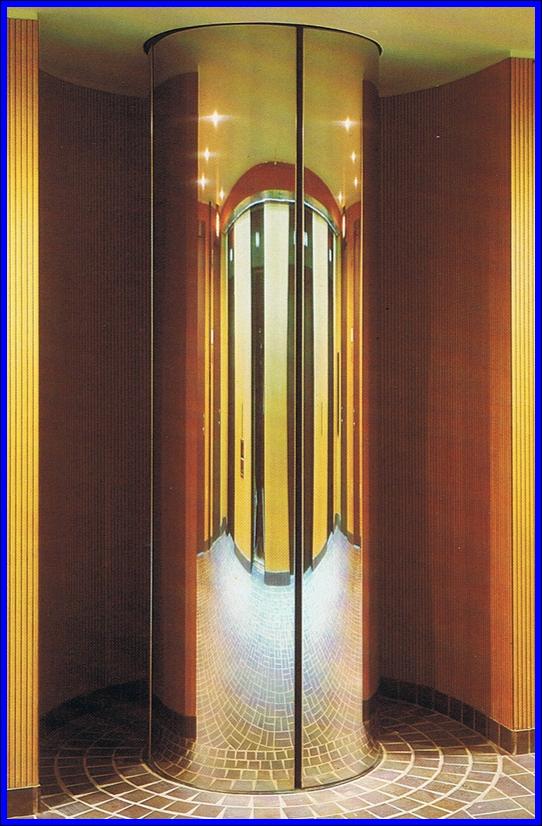

- #4 Brushed

- #8 Mirror

- #9 Bead Blast

- Embossed

- Hand Patterned

- Fine for high traffic areas

- Mechanically Patterned

Alternative to Bead Blast is an embossed product “Softex” that gives the bead blast look while less apt to show fingerprints. |